|

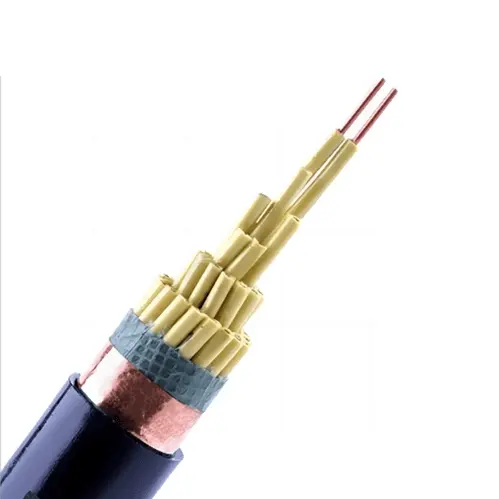

PVC Insulated Shielded Control Cable |

|||||

|

Voltage |

Type |

Structure |

Description |

No. of Cores & Nominal Section Area |

|

|

450/750V

600/1000V

|

KVVP |

cu/pvc/(is)os/pvc |

copper core, pvc insulated, (aluminum foil individual shielded), copper wire braided overall shielded, pvc sheathed, control cable |

2 core, 3 core, 4 core, 5 core, 7 core, 8 core, 10 core, 12 core, 14 core, 16 core, 19 core, 24 core, 27 core, 30 core, 37 core, 44 core, 52 core, 61 core, or as your request

(0.2mm², 0.3mm², 0.5mm² , 0.75mm² , 1mm², 1.5mm², 2.5mm², 4mm², 6mm², 10mm²)

1 pair, 2 pairs, 3 pairs, 4 pairs, 5 pairs, 7 pairs, 8 pairs, 10 pairs, 12 pairs, 16 pairs, 19 pairs, 24 pairs, or as your request

(0.2mm², 0.3mm², 0.5mm² , 0.75mm² , 1mm², 1.5mm², 2.5mm²) |

|

|

KVVP2 |

cu/pvc/(is)os/pvc |

copper core, pvc insulated, (aluminum foil individual shielded), copper tape overall shielded, pvc sheathed, control cable |

|||

|

KVVRP |

cu/pvc/(is)os/pvc |

copper core, pvc insulated, (aluminum foil individual shielded), copper wire braided overall shielded, pvc sheathed, flexible control cable |

|||

|

KVVRP32 |

cu/pvc/(is)os/swa/pvc |

copper core, pvc insulated, (aluminum foil individual shielded), copper wire braided overall shielded, steel wire armoured, pvc sheathed, flexible control cable |

|||

|

KVVP2-32 |

cu/pvc/(is)os/swa/pvc |

copper core, pvc insulated, (aluminum foil individual shielded), copper tape overall shielded, steel wire armoured, pvc sheathed, control cable |

|||

|

Note: Flame retardant control cable and fire resistant control cable are also available. |

|||||

|

XLPE Insulated Shielded Control Cable |

|||||

|

Voltage |

Type |

Structure |

Description |

No. of Cores & Nominal Section Area |

|

|

450/750V

600/1000V

|

KYJVP |

cu/pvc/(is)os/pvc |

copper core, xlpe insulated, (aluminum foil individual shielded), copper wire braided overall shielded, pvc sheathed, control cable |

2 core, 3 core, 4 core, 5 core, 7 core, 8 core, 10 core, 12 core, 14 core, 16 core, 19 core, 24 core, 27 core, 30 core, 37 core, 44 core, 52 core, 61 core, or as your request

(0.2mm², 0.3mm², 0.5mm² , 0.75mm² , 1mm², 1.5mm², 2.5mm², 4mm², 6mm², 10mm²)

1 pair, 2 pairs, 3 pairs, 4 pairs, 5 pairs, 7 pairs, 8 pairs, 10 pairs, 12 pairs, 16 pairs, 19 pairs, 24 pairs, or as your request

(0.2mm², 0.3mm², 0.5mm² , 0.75mm² , 1mm², 1.5mm², 2.5mm²)

|

|

|

KYJVP2 |

cu/pvc/(is)os/pvc |

copper core, xlpe insulated, (aluminum foil individual shielded), copper tape overall shielded, pvc sheathed, control cable |

|||

|

KYJVRP |

cu/pvc/(is)os/pvc |

copper core, xlpe insulated, (aluminum foil individual shielded), copper wire braided overall shielded, pvc sheathed, flexible control cable |

|||

|

KYJVRP32 |

cu/pvc/(is)os/swa/pvc |

copper core, xlpe insulated, (aluminum foil individual shielded), copper wire braided overall shielded, steel wire armoured, pvc sheathed, flexible control cable |

|||

|

KYJVP2-32 |

cu/pvc/(is)os/swa/pvc |

copper core, xlpe insulated, (aluminum foil individual shielded), copper tape overall shielded, steel wire armoured, pvc sheathed, control cable |

|||

|

Note: Flame retardant control cable and fire resistant control cable are also available. |

|||||

|

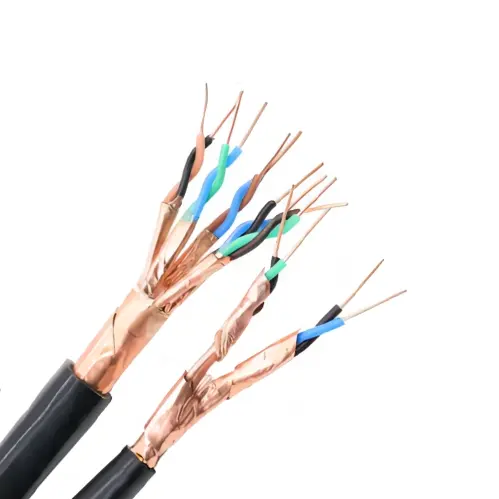

Instrument Control Cable |

|||||

| Voltage | Type |

Structure |

Description |

Cores |

Nominal Section |

|

450/750V |

JVVP |

cu/pvc/os/pvc |

copper core, pvc insulated, copper wire braided shielded, pvc sheathed, instrument control cable |

2 core, 3 core, 4 core, 5 core, 7 core, 8 core, 10 core, 12 core, or as your request

1 pair, 2 pairs, 3 pairs, 4 pairs, 5 pairs, 7 pairs, 8 pairs, 10 pairs |

0.2mm² 0.3mm² |

|

450/750V |

JYVP |

cu/pe/os/pvc |

copper core, pe insulated, twisted into pairs, aluminum foil individual shielded, all pairs twisted, copper wire braided overall shielded, pvc sheathed, instrument control cable |

||

|

300/500v |

DJYJVP |

cu/pe/is/os/pvc |

copper core, pe insulated, twisted pair, copper wire braided shielded, pvc sheathed, instrument control cable |

||

| Voltage: | 300/500V, 450/750V, 600/1000v |

| Conductor: | Annealed Copper or Tinned Copper (solid core class1, stranded core class2 or flexible core class5) |

| Insulation: | Polyvinyl chloride (PVC) or Crosslinked Poyethylene (XLPE) or Polyethylene (PE) |

| Shield Type: | Copper tape shielded (cts) Copper wire braided shielded (cws) Aluminum foil shielded |

| Armour Type (optional): | steel tape armoured (sta) steel wire armoured (swa) |

| Outer Sheath: | Polyvinyl chloride (PVC), Polyethylene (PE) or LSZH (optional) |

| Standards: | IEC/EN/BS/UL/CSA |

| Certifications: | CB Test Certificate/CCC/ISO 9001/ISO 14001 |

| Additional: | *FR, FRLS, LSZH, LSOH, LSHF control cables are also available. *Our custom cable services are designed to meet your specific requirements. |

XLPE Material:

Max. service temperature: 90 ℃

Min.temperature when installation: 0℃

Max. short-circuit temperature: 250℃(max. 5s)

Min. service temperature: -40℃(fixed and protected installations)

Max. service temperature: 70 ℃

Min.temperature when installation: 0℃

Max. short-circuit temperature: 160℃(max. 5s)

Min. service temperature: -40℃(fixed and protected installations)

|

Item |

Min.bending radius |

|

Unarmored Control Cable |

Not less than 6D |

|

Armored or Shield Control Cable |

Not less than 12D |

|

Shield Flexible Control Cable |

Not less than 6D |

|

*D means overall diameter of cables |

|

|

Our History

|

Production Capabilities

|

Innovation & Customization

|

From high-purity materials to advanced manufacturing processes, we ensure every cable delivers top-tier performance and long-term reliability.

Our cables are flame retardant, eco-friendly, and fully compliant with international safety standards, ensuring peace of mind for your projects.

We provide tailored cable solutions to meet your exact specifications, ensuring optimal performance for your unique applications.

Certified by CCC, ISO, IEC etcs. our products meet the highest global quality and safety benchmarks.

With 24/7 customer support, technical expertise, and a one-year warranty, we are committed to your success every step of the way.

As a leading global cable manufacturer, Huanghe Cable combines cutting-edge technology with decades of expertise to deliver high-performance cables and reliable service. Whether you're a distributor, trader, or contractor, we are your trusted partner for all your power transmission needs.

At Huanghe Cable, we don’t just sell cables, we deliver solutions that power your projects and drive your success. Contact us today to request a quote, discuss your requirements, or learn more about how we can support your business.

Please contact us for a free quotation by the below form. We promise the quickest response within 8 hours.